Select Delivery Method

Please enter your delivery address to check availability.

Please select your click and collect pick up Branch to check availability.

What is Intrinsically Safe Design and When Do I Need It?

Oil rigs, coal mines, sewerage plants and pharmaceutical factories are just some of the industries where fire and explosions are a genuine threat on any given day. In these environments, flammable gasses, vapours or dust, combined with oxygen and an ignition source can combust, causing fire and explosions.

One of the most common ignition sources at these sites are the sparks and hot surfaces generated from common electronic devices. To avoid potential disaster, it is crucial that equipment which is used in these hazardous areas takes an Intrinsic Safety design approach.

What is Intrinsic Safety?

Intrinsic safety equipment is specially designed for contact with explosive gases, vapours and dust. These devices avoid ignition through minimising both the available power and the maximum temperature of a device, thus eliminating potential for sparks and hot surfaces.

While these devices store less energy and generate less heat, the performance of the device is not compromised.

Intrinsically safe design technique is accepted throughout the world as a solution to problems of hazardous areas (for equipment requiring limited power) with international standards and legislation from IEC Ex, ATEX and OSHA providing certification of intrinsically safe devices.

Hazardous area classification

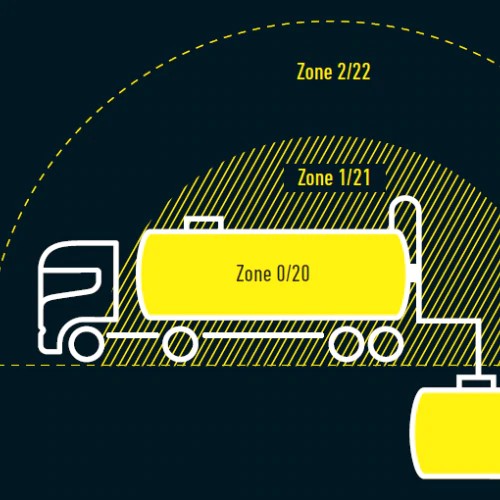

Hazardous areas are classified into different exclusion zones. Intrinsically safe devices may be compliant for use in some or all of these zones.

Exclusion zones are divided into 0, 1 or 2 based on the probability of a flammable atmosphere being present.

ZONE 0/20:

Working areas in which explosive atmospheres in the form of flammable gases, vapours or dust clouds (e.g. in gas tanks or grain silos) prevail predominantly.

ZONE 1/21:

Working areas in which explosive atmospheres in the form of flammable gases, vapours or dust clouds prevail occasionally.

ZONE 2/22:

Working areas in which explosive atmospheres in the form of flammable gases, vapours or dust clouds (e.g. in case of a gas leak) usually do not prevail / prevail only for a short time.

Intrinsically Safe Devices

Intrinsically safe devices help to increase the level of safety on the jobsite without compromising job performance.

Types of devices which may be suitable for intrinsically safe design include flashlights, cameras, gas detectors and work radios. Always ensure devices possess the correct certification for use in Australia and are suitable for your specific application.